Home > Products > sand blasting room > high quality blast chamber made in China

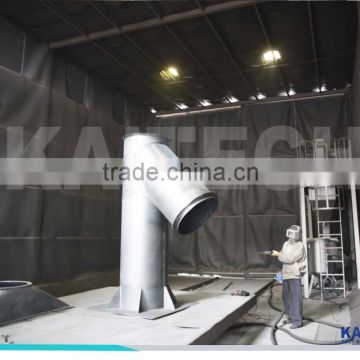

high quality blast chamber made in China

- qingdao

- T/T

You May Like

Product Details

| Condition | New | Place of Origin | Shandong, China | |

| Brand Name | KAITECH | Model Number | kt | |

| Feature | Other | Fuel | Electric | |

| Certification | CE | Use | Other, surface cleaning | |

| Cleaning Process | Other, blasting media | Cleaning Type | Manual | |

| Industry Used | Pharmaceutical Cleaning | Material | Metal / Coil | |

| Power(W) | Three Phase380v | Dimension(L*W*H) | Customized | |

| After-sales Service Provided | Overseas service center available |

Product Description

high quality blast chamber made in China

1, Workpiece to be cleaned:

No. | Name | Technical parameters | Remarks |

1 | workpiece | Size of max workpiece:1400*2400*1600mm,heaviest weight: 1.5T | transformer |

2 | Cleaning aim | Remove oxide skin, welding slag and other fixture to remove surface stress, and improve adhesive force on surface. |

2, Performance

- The mechanic recovery blasting room adopts mechanic recovery system to recovery abrasives and the abrasives can be chosen according to requirements. The abrasive usage is high and process productivity is also high.

- The dust removing system adopts two stages dust removing, and the dust removing efficiency can reaches 99.99%.

- The air flow in ventilation in this kind of blasting room can be adjustable to prevent the abrasives from entering cartridge filters. Thus it can reduce the lost of abrasives and can have a good dust removing efficiency.

- The main electrical elements in this blasting room uses Japan/EU/USA brand. They have the advantages of reliability, safety, long life service and easy maintenances.

- Use widely: It applies to middle and small size of blasting room to do pretreatment jobs such as rough, casting, welding, heating, steel structure, container, transformer shell, special parts and so on.

(2) Mechanic recovery blasting room size

No. | Model | Size of room | Size of jobs | Spray gun quantity |

1 | XDL-0606-M1 | 6000×6000×5000mm | 3000×3000×2500mm | 2 |

2 | XDL-0606-M2 | 6000×6000×6000mm | 3000×3000×3500mm | 2 |

3 | XDL-0806-M1 | 8000×6000×5000mm | 5000×3000×2500mm | 2 |

4 | XDL-0806-M2 | 8000×6000×6000mm | 5000×3000×3500mm | 2 |

5 | XDL-1006-M2 | 10000×6000×6000mm | 7000×3000×3500mm | 2 |

6 | XDL-1506-M2 | 15000×6000×6000mm | 12000×3000×3500mm | 2 |

7 | XDL-1508-M2 | 15000×8000×6000mm | 12000×5000×3500mm | 2 |

8 | XDL-1808-M2 | 18000×8000×6000mm | 15000×5000×3500mm | 4 |

9 | XDL-0806-M3 | 18000×10000×8000mm | 15000×7000×5500mm | 4 |

Remarks:

- Because of different size of blasting jobs from different customers and different productivity requirements, customers may need different size of blasting room. Above size of blasting room is for customers' reference. When you have different requirements, please let us know the size of blasting jobs, size of blasting room and quantity of spray guns, we can design blasting room according to your requirements.

3, Working procedure:

1. Open dust collector

2. Open separator

3. Open elevator

4. Open belt conveyor

5. Open light

6. Load workpieces in trolley

7. After trolley arrives at fixed position, close blasting booth door

8. Operators do shot peening, surface cleaning starts

9. After cleaning is finished, open blasting booth door

10. Trolley leave blasting booth, turn over workpieces, repeat step 7, 8, 9

11. Trolley returned to unloading station, unload workpieces.

12. Repeat 6, 7,8,9,10,11 steps

13. If you prepare to stop work, turn to step 14.

Biggest manufacturer of sand blasting booth, shot blasting machine, spare parts and metal abrasive in China. 1700 emplyees, products have exported to more than 40 countries and regions.

Products have got CE,ISO9001 international standards.

Main markets: Aisa, Middle East, North of America,South of America and so on.

1.We can provide comprehensive shot-peening and shot blasting solution

2.we can offer OEM service.

3.Our main market of shot blasting machine :worldwide,South-east,Middle-east ,Europe and South America.

4.Our shot blasting spare parts are high quality.Blaster can reach uttermost long-life , environmental protection, high efficiency in service.

Q 1: Do you have after-sale service?

A : yes, we have perfect after-sale service

Q 2: How long can your spare parts be used?

A: Blade, control cage and distributor are high chrome, and can be used for more than 2000 hours.

Kinds of guard board can be used for more than 3000 hours.

Q 3: Where is your factory?

A: We are near Jinan Airport, you are welcome to be Jinan Airport and then we will arrange car to pick you up there. Sincerely welcome here to investigate our factory in person.

Q 4. How about your company ?

A:Our company is the biggest manufacturer of metal abrasive and shot blasting machine in china , we have exported to more than 30 counries and regions , and got good comments from overseas and domestic.

any question,contact with joyce easily 0086-15965017759

Contact Us

- Shandong Kaitai Shot Blasting Machinery Share Co., Ltd.

- Contact nameBecky zou Chat Now

- Phone0086-0531-88938987

- Addressqingyang,zouping, Binzhou, Shandong

Product Categories

| blast media | blast pot spare parts | dehumidifier | Flexible door |

| New Products | painting room | sand blast pots | sand blasting room |

| suction sand machine |

New Products

-

sand blasting room/sandblasting booth

-

Kaitech Sand Blaster KP-0.06-JX

-

Sand Blasting Room For Large Metal Blasting

-

sand peening room with high quality

-

Blasting Room For Sand Peening

-

Sand blasting room/shot peening room for Steel Fabricators/Construction Equipment

-

Sand Blast Chamber / Shot Blasting Booth / Sand Blasting Room

-

Automatic Recovery System Sand Blasting Chamber Room

-

Shot/Sand Blasting Room with CE certificate

-

Machanical recovery automatic recycling sand blasting booth

-

Pneumatic recovery sand blasting booth

-

Blasting Rooms, Sand blasting booths with high quality

Popular Searches

- shot blasting

- Shot Blasting Machine

- Shot Blast Cleaning Equipment

- Sand Blaster Equipment

- sand blaster

- shot blasting equipment

- Sand Blasting Machine

- Sand Blasting Nozzle

- Blasting Machine

- Blasting Cleaning Machine

- Shot Blasting Cleaning Machine

- Floor Shot Blasting Machine

- Blasting Equipment

- Shot Blast Cleaning Machine

- sandblasting cabinet

- sand cleaning machine

- shot blast machine

- sand blasting room

- sand blasting cabinet

- Sand Blasting Cleaning Machine

- Sand Blaster Machine

- Shot Peening Machine

- Automatic Sandblast Machine

- Sand Blast Machine

- compressed air nozzle

- air blast nozzle

- used sandblasting equipment for sale

- portable sand blaster

- glass blaster

- sandblaster set

Recommended Products

- Tumble type conveyor rubber belt type sand blaster shot blasting machine

- Tumble type conveyor rubber belt type sand blaster shot blasting machine

- Sand blasting line for enamel water heater production

- Dry and wet metal sand blasting machine low price for sale wheel sandblasting shanghai

- Gubot dustless vapor sand blasting cabinet water sandblast equipment sandblaster machine

- Gubot Car Wheel sandblasting machine for Heavy duty parts

- Gubot automatic sandblasting machine automatic glass sandblasting machine

- clemco sandblasting machine granite sandblasting machine from China Gubot

- China Gubot Sandblasting machine sandblaster headstone sandblasting machine

- Gubot hot sale sandblasting machine automatic internal pipe sandblasting machine

- Gubot hot sale wet type sandblasting machine sandblaster industrial machine

- sandblasting machine price glass machine sandblasting Gubot

Find Similar Products By Category

- Industrial Equipment & Components > Cleaning Machine > Sandblaster

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Becky zou

Hi there! Welcome to my shop. Let me know if you have any questions.

Becky zou

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile